|

A modern book sewing machine works through the following steps:

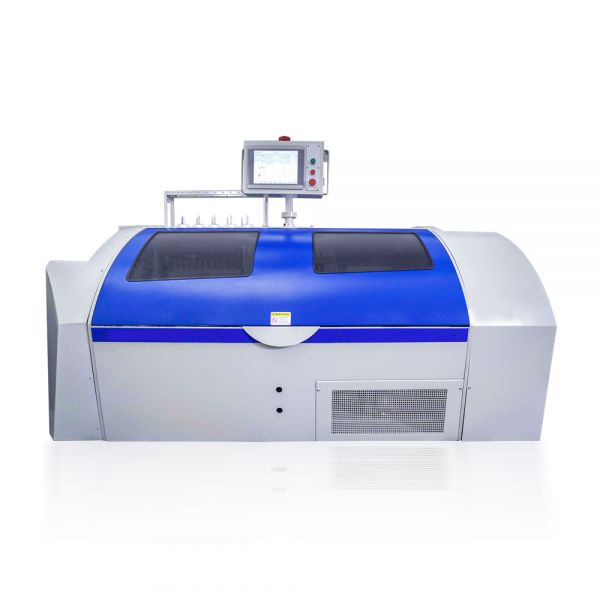

HX180 Automatic Book Sewing Machine

- The first step is to have the book pages folded into signatures. Signatures are groups of pages that are folded together in a specific order, usually multiples of 8,16 or 32 pages

- The signatures are then placed in the machine's feeding mechanism. This can be either manual or automatic, depending on the type of machine. Automatic machines have conveyor belts or rollers that pick up the signatures one by one and transport them to the sewing area.

- The machine is threaded with a strong and durable thread, usually nylon or polyester. The thread is passed through the eye of the needle, which is attached to a needle bar. The needle bar is driven by a motor and moves up and down rapidly.

- As the needle moves down, it pierces through the folded edge of the signature, carrying the thread with it. When the needle reaches its lowest point, it forms a loop on the other side of the signature.

- A hook or shuttle mechanism, located below the signature, rotates in sync with the needle's movement. The hook catches the loop formed by the needle and wraps it around another thread, usually from a bobbin. This creates a lock stitch, which is a strong and durable stitch that holds the signatures together.

- The machine continues to feed the signatures forward while the needle and hook work in tandem to create a continuous line of stitches along the folded edge of the signatures. The stitches are evenly spaced and tightly formed to ensure the book is bound securely1.

- Some modern book sewing machines can also create different stitching patterns, such as double stitching or decorative stitches, depending on the settings and requirements.

- Once the sewing is complete, the machine may automatically tie off the thread to form a knot, securing the end of the stitch. It then cuts the thread cleanly, leaving a neat finish.

- The sewn signatures are then either stacked together to form a book block or further processed by adding covers, endpapers, and other finishing touches to complete the bookbinding process

- Many modern book sewing machines are integrated with computer systems. Operators can input various parameters such as book size, number of signatures, stitch type, and thread tension through a touchscreen or computer interface.

- The computer then controls the machine's mechanisms to ensure precise and consistent stitching according to the specified settings. This allows for efficient production of different book formats and sizes, as well as customization of the binding process.

|