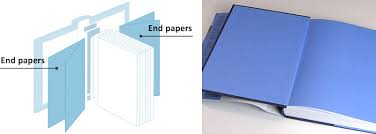

Solve Your Toughest Binding Challenges with an Automatic End Sheet Pasting and Paper Inserting Machine

|

Every printing and binding factory faces a common set of post-press challenges: misaligned signatures, messy glue application, high labor costs, and production slowdowns. These issues can lead to wasted materials, missed deadlines, and dissatisfied clients. The Automatic End Sheet Pasting and Paper Inserting Machine is engineered as a comprehensive solution, directly addressing and overcoming these persistent problems with its intelligent and efficient design. Challenge #1: Inaccurate Signature Registration. Manually inserting signatures or using less advanced machinery can often lead to misaligned pages. This machine solves this with its signature gripping structure, which is as stable and reliable as a dedicated collating machine. It also boasts a wide range of applications, capable of registering all kinds of signatures, including tricky two-up or accordion folds, ensuring every book block is perfectly squared and ready for binding.  Challenge #2: Inconsistent and Messy Gluing. Applying glue for end sheets can be a messy affair, with excess adhesive ruining the aesthetic of the final product. The machine’s extruding gluing method provides the perfect antidote. It delivers a precise, controlled amount of glue exactly where it's needed. This method is easy to adjust, eliminating guesswork and ensuring a clean, strong bond every time, transforming a difficult task into a simple, automated process.  Challenge #3: High Defect Rates and Material Waste. Undetected errors like missing or double-fed pages are a major source of waste. The Automatic End Sheet Pasting and Paper Inserting Machine tackles this head-on with its accurate electromechanical detectors. The system automatically stops production the moment an error is found, preventing the waste of paper, ink, and glue on a faulty product. This proactive quality control dramatically improves the yield from your raw materials.  Challenge #4: Production Bottlenecks and High Labor Costs. The dual-functionality of this machine is the ultimate answer to workflow inefficiency. By combining inserting and pasting, it eliminates a full step in the production line, saving time and reducing the number of operators needed. With its high-speed operation and user-friendly touch screen, it empowers a single operator to achieve a level of output that would otherwise require a whole team, directly addressing the challenge of rising labor costs. In short, this machine is a problem-solver by design. |

| Tag:End Sheet,End Sheet Pasting,Paper Inserting Machine,book binding |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!