HX2000 Notebook Ribbon Inserting Machine transforms the ribbon insertion process into a seamless, fully automated workflow.

|

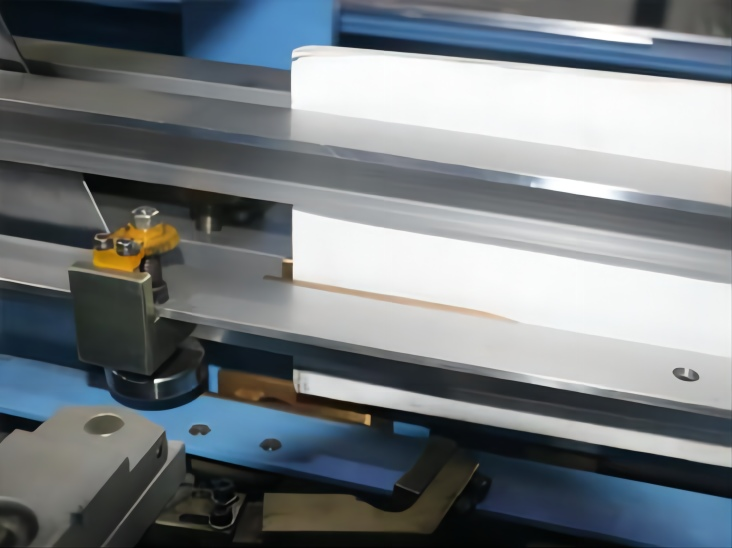

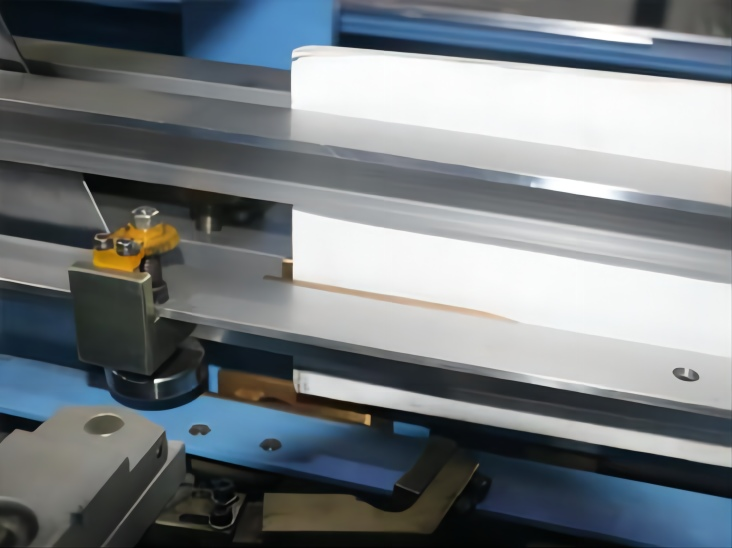

Overview The HX2000 Notebook Ribbon Inserting Machine transforms the ribbon insertion process into a seamless, fully automated workflow. Whether running as a stand-alone unit or integrated into a hardcover production line, its sophisticated mechanics ensure consistency for every book produced.  Step-by-Step Operation  1. Automatic Feeding: Books are loaded onto a continuous feeding conveyor, which separates and positions them for processing.  2. Smart Splitting: The machine utilizes a specialized dividing mechanism and a heated splitting device to open the book block at the exact center or desired location without damaging the pages. 3. Ribbon Insertion: The ribbon is pulled from the roll, measured to the precise length via the PLC touchscreen system, and inserted deeply into the book block. 4. Cutting & Gluing: An electric heating cutter slices the ribbon to the pre-set angle. Simultaneously, the Nordson system sprays hot melt glue onto the spine head, and a fixing scraper presses the ribbon down for a permanent bond. 5. Finishing: The ribbon tail is automatically tucked back into the book pages to prevent tangling during downstream processing. Technical Superiority Powered by a 6KW system and requiring 6bar air pressure, the HX2000 Notebook Ribbon Inserting Machine is built with a robust iron frame weighing 1000kg, ensuring stability during high-speed operation. It is the ultimate technical solution for modern bookbinding. |

| Tag:HX2000 Notebook Ribbon Inserting Machine,ribbon insering machine,notebook ribbon,diary ribbon,ribbon inserter |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!